Multi-Surface Application: Cleans and prepares steel, asphalt, and concrete surfaces.

Efficient Performance: Removes coatings, paint, rubber, and markings effectively.

Dust-Free Operation: Integrated vacuum system ensures clean and safe usage.

Improves Adhesion: Creates textured surfaces ideal for new coatings.

Skid Resistance: Enhances grip on sidewalks, roads, and runways.

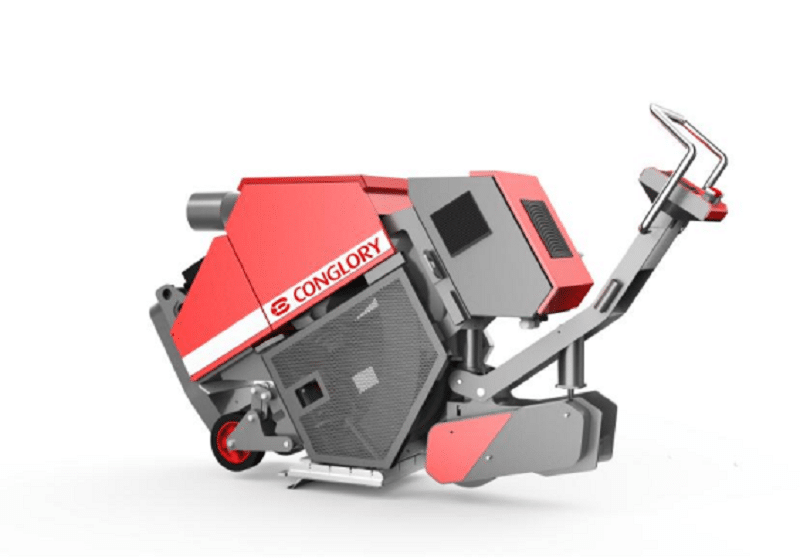

Shot Blast Machine for Concrete floors | Wheelabrator Shot Blast Machine Used for Preparing, Steel, Asphalt, and Concrete Surfaces

$18,500.00 Original price was: $18,500.00.$18,250.00Current price is: $18,250.00.

The Shot Blast Machine for Concrete Floors or Wheelabrator Shot Blast Machine is a versatile and efficient tool for preparing steel, asphalt, and concrete surfaces. It effectively removes dirt, coatings, paint, and other contaminants, creating a clean, textured surface ideal for new coatings or toppings. This high-performance machine improves adhesion and enhances the durability of applied finishes, making it essential for industrial and commercial surface preparation projects.

This shot blast machine works by propelling abrasive media at high speeds onto the surface. The process removes unwanted layers, roughens the surface for better adhesion, and improves skid resistance for applications like sidewalks, roads, and runways. It also features a vacuum system that collects dust and debris, ensuring nearly dust-free operation. Whether it’s for removing markings, improving aesthetics, or preparing large industrial floors, this machine delivers outstanding results.

Shot Blast Machine for Concrete floors | Wheelabrator Shot Blast Machine Used for Preparing, Steel, Asphalt, and Concrete Surfaces

The Wheelabrator Shot Blast Machine is designed for efficiency and precision, with various configurations like table, tumble, or continuous flow machines to meet different project needs. Its advanced features, such as adjustable intensity, abrasive recycling, and dust collection, ensure a safe and clean working environment. Suitable for steel, concrete, and asphalt surfaces, this machine is the go-to solution for surface preparation in industries ranging from construction to aerospace.

Key Features

Durable Performance

Robust Design

Enhanced Productivity

Cost-Effective Solution

| Weight | 380 kg |

|---|---|

| Item No.: |

CB 1-10E |

| Product Origin: |

Fujian, China |

| Shipping Port: |

Xiamen |

| Lead Time: |

7-20 Days |

| Working Width: |

250MM |

| Walking Speed: |

0-23M/MIN |

| Shot Blasting Power: |

15HP 380V 3P 50HZ / 220V 3P 60HZ |

| Blasting Efficiency |

>150m2/h |

Sink Hole Cutting Machines

Sink Hole Cutting Machines Stone Carving Routers

Stone Carving Routers Pneumatic Stone Profiling Machine

Pneumatic Stone Profiling Machine Electric Stone Profiling Machine

Electric Stone Profiling Machine Polishing Machines

Polishing Machines Floor Machines

Floor Machines

Tile Vibrators

Tile Vibrators Miter Equipment

Miter Equipment Miter Rail Type Machines

Miter Rail Type Machines Suction Cups

Suction Cups Grout Removal Machine

Grout Removal Machine Manual Tile Cutters

Manual Tile Cutters

Blades

Blades Diamond Bits

Diamond Bits Grinding Tools

Grinding Tools Grinding Cup Wheel

Grinding Cup Wheel Profiling Tools

Profiling Tools Polishing Tools

Polishing Tools Polishing Pads

Polishing Pads Tile Cutting Saw Blades

Tile Cutting Saw Blades Tile Drill Bits

Tile Drill Bits Lifting Equipment

Lifting Equipment Carry clamps

Carry clamps Suction Cups

Suction Cups Stone Slab Trolley

Stone Slab Trolley Work Tables

Work Tables Measuring Tools

Measuring Tools

CNC Accessories

CNC Accessories

Air Grinders

Air Grinders Angle Grinders

Angle Grinders Slotting Machines

Slotting Machines Drill Machines

Drill Machines

Dust Collectors

Dust Collectors Construction Gear

Construction Gear

Reviews

There are no reviews yet.