Advanced Four-Impeller System: Ensures uniform and efficient blasting coverage.

Durable Performance: Service life of 5000-8000 m² per set for long-lasting operation.

Comprehensive Cleaning: Simultaneously shakes out, removes the core, and cleans castings.

Robust Design: Includes one Four-Impeller and one Directional Sleeve per set.

High-Speed Projectiles: Delivers powerful cleaning and surface strengthening.

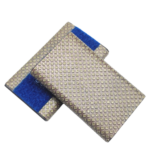

Four Impeller

$2,500.00 Original price was: $2,500.00.$2,250.00Current price is: $2,250.00.

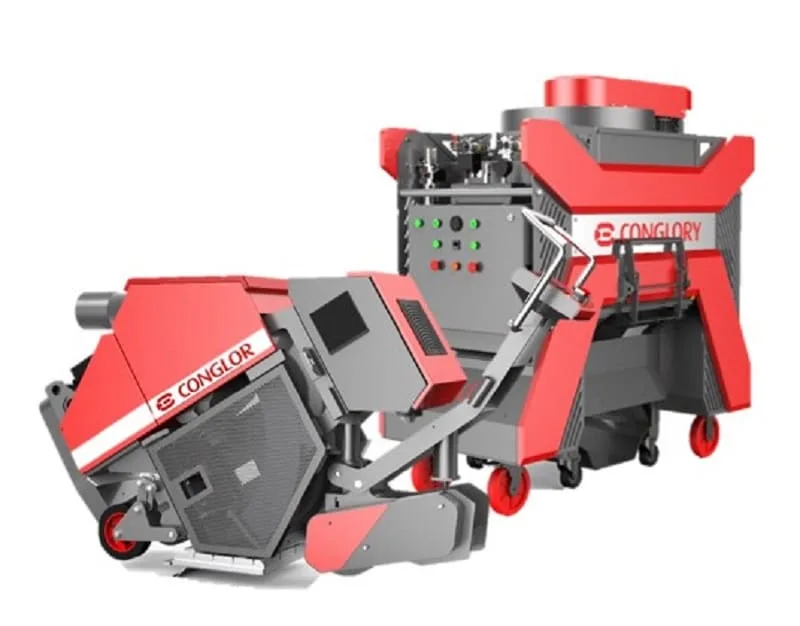

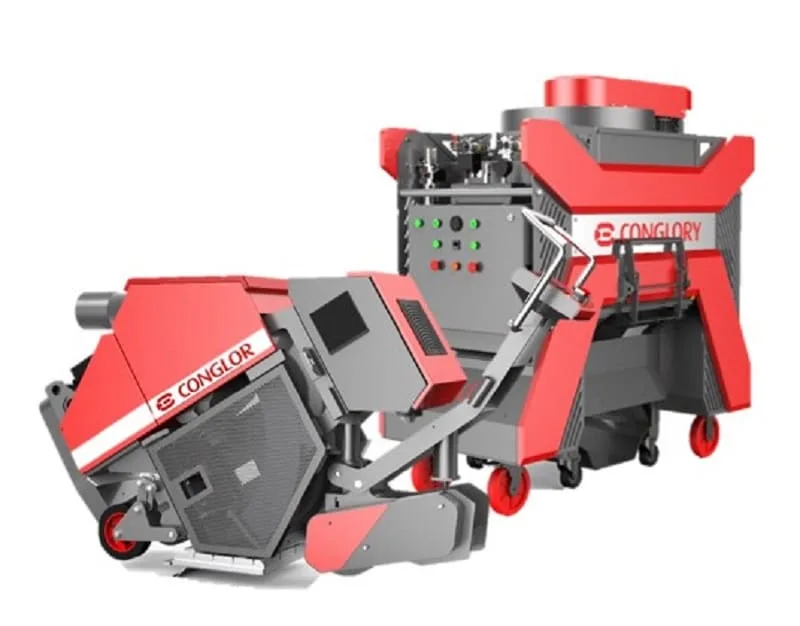

The Four-Impeller Hot Blasting Machine is a high-performance casting equipment designed to clean, shake out, and strengthen the surface of castings. Utilizing high-speed projectiles, this machine ensures thorough cleaning and core removal, making it an indispensable tool in the casting and foundry industries. Its advanced four-impeller system delivers uniform blasting coverage, resulting in smooth and flawless surfaces.

With a robust service life of 5000-8000 m² per set, the machine is built for durability and long-term efficiency. Each set includes one Four-Impeller and one Four-Impeller Directional Sleeve, ensuring optimal functionality and precise performance. This powerful combination not only enhances productivity but also reduces operational downtime by delivering consistent and reliable results.

Four Impeller

The Four-Impeller Hot Blasting Machine is engineered to meet the demanding needs of modern casting facilities. Its efficient cleaning mechanism and durability make it a cost-effective solution for improving surface quality and ensuring the integrity of cast components. This machine is an essential addition for industries looking to achieve precision and efficiency in casting processes.

Key Features

Durable Performance

Robust Design

Enhanced Productivity

Cost-Effective Solution

| Weight | 5 kg |

|---|---|

| Item No.: |

Four impeller |

| Product Origin: |

Fujian, China |

| Color: |

Black |

| Min Order: |

50 |

| Product Weight: |

5 |

| Shipping Port: |

Xiamen |

| Lead Time: |

7-20 Days |

Sink Hole Cutting Machines

Sink Hole Cutting Machines Stone Carving Routers

Stone Carving Routers Pneumatic Stone Profiling Machine

Pneumatic Stone Profiling Machine Electric Stone Profiling Machine

Electric Stone Profiling Machine Polishing Machines

Polishing Machines Floor Machines

Floor Machines

Tile Vibrators

Tile Vibrators Miter Equipment

Miter Equipment Miter Rail Type Machines

Miter Rail Type Machines Suction Cups

Suction Cups Grout Removal Machine

Grout Removal Machine Manual Tile Cutters

Manual Tile Cutters

Blades

Blades Diamond Bits

Diamond Bits Grinding Tools

Grinding Tools Grinding Cup Wheel

Grinding Cup Wheel Profiling Tools

Profiling Tools Polishing Tools

Polishing Tools Polishing Pads

Polishing Pads Tile Cutting Saw Blades

Tile Cutting Saw Blades Tile Drill Bits

Tile Drill Bits Lifting Equipment

Lifting Equipment Carry clamps

Carry clamps Suction Cups

Suction Cups Stone Slab Trolley

Stone Slab Trolley Work Tables

Work Tables Measuring Tools

Measuring Tools

CNC Accessories

CNC Accessories

Air Grinders

Air Grinders Angle Grinders

Angle Grinders Slotting Machines

Slotting Machines Drill Machines

Drill Machines

Dust Collectors

Dust Collectors Construction Gear

Construction Gear

Reviews

There are no reviews yet.