Durable Construction: Made from high-quality materials for long-lasting use in heavy-duty applications.

Perfect for Stone Slab Stitching: Ideal for joining mitered edges of stone, marble, granite, and other hard surfaces.

Precise Alignment: Provides secure and accurate edge alignment for flawless installations.

Easy Adjustment: Adjustable design for a firm grip and versatile application on different stone thicknesses.

Ergonomic Design: Comfortable and easy-to-use, reducing fatigue during extended use.

Multi-Purpose: Perfect for a variety of stone installation tasks, including countertops, tables, and other stone features.

Set of 2 Clamps: Provides balanced support for stone slab stitching tasks.

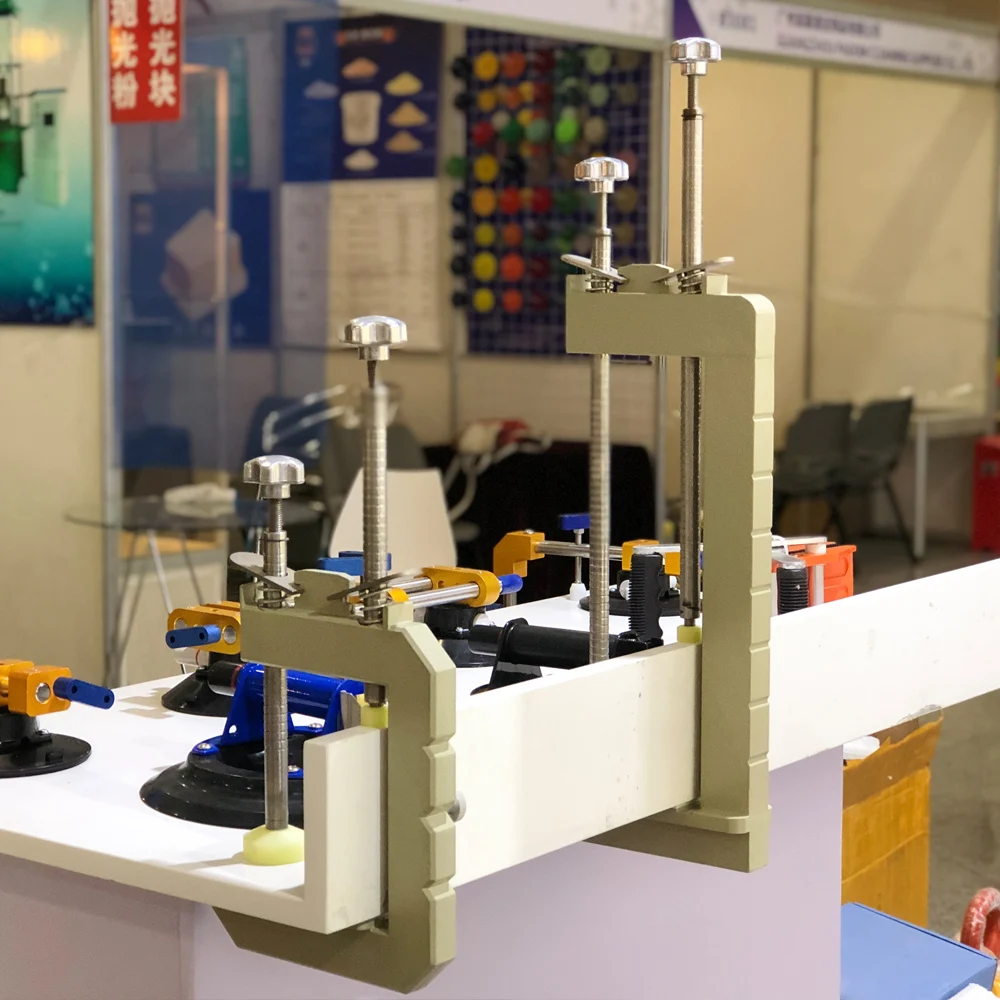

Stone Miter Clamps | Miter Clamps for Stone | Install tooling tools for stone slab stitching | 2 pieces

$298.00 Original price was: $298.00.$240.00Current price is: $240.00.

17 in stock

The Stone Miter Clamps are specialized tools designed for precision and efficiency in stone slab stitching and installation. These clamps are ideal for joining mitered edges of stone, granite, marble, and other hard surfaces, providing a secure and reliable hold during the cutting, alignment, and stitching processes. Crafted from high-quality materials, these clamps offer strength, durability, and ease of use, making them a must-have for stone fabricators, installers, and professionals working with stone slabs.

This set of 2 Stone Miter Clamps allows for easy adjustment and secure fastening, ensuring that stone edges are perfectly aligned for seamless installation. Whether you’re working on countertops, tabletops, or other stone applications, these clamps provide the support needed to achieve precise, clean joints. The ergonomic design allows for a comfortable grip and efficient operation, while the robust construction ensures that the clamps will perform reliably on even the toughest stone materials.

Stone Miter Clamps | Miter Clamps for Stone | Install tooling tools for stone slab stitching | 2 pieces

Key Features

Stone-Miter-Clamps

Miter-Clamps-Set-for-Stone

Stone-Edge-Alignment-with-Miter

Powerful Device

| is_customized |

No |

|---|---|

| Model Number |

RZMC45 |

| Material |

Stainless Steel |

| Product Name |

stone mitre clamp |

| Application |

Granite, marble, engineered stone |

| Usage |

edge stone slab stitching |

| Type |

2 pieces/set |

Reviews

There are no reviews yet.