-

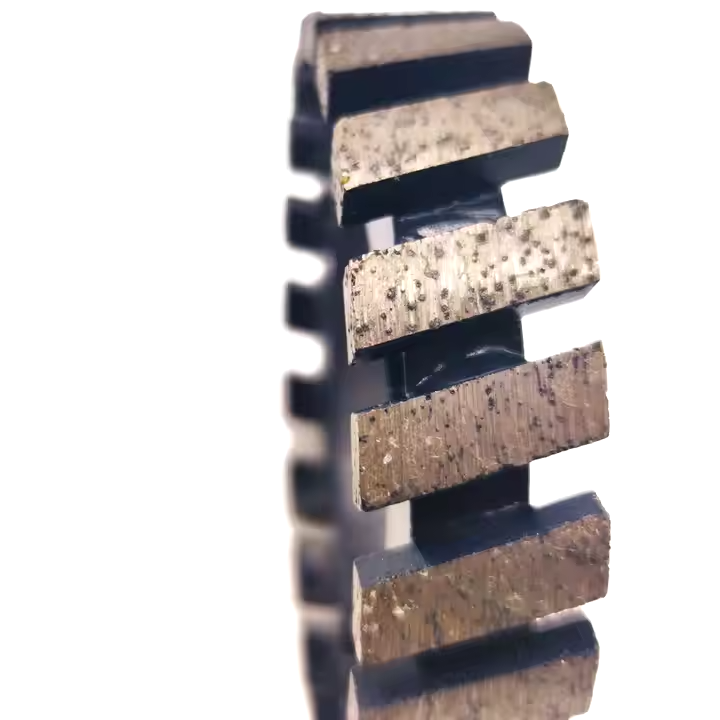

Durable Diamond Segments – High-quality diamond composition ensures maximum cutting efficiency and extended wheel life.

-

Precision Surface Calibration – Ideal for accurately grinding and leveling granite, marble, and engineered stone surfaces.

-

Adjustable Shank Options – Compatible with multiple CNC machines, offering 1/2” gas flange and various diameter options (D50/86/100mm).

-

Smooth Polishing Finish – Achieves a clean, polished surface with minimal effort, perfect for professional stone applications.

-

High Processing Efficiency – Designed for heavy-duty, high-speed grinding, allowing faster material removal and productivity.

-

Robust Iron Core – Provides stability and support, ensuring consistent performance across extensive use.

-

Flexible Sizing – Available in multiple diameters and segment heights, adapting to diverse project requirements.

-

Dust-Proof Construction – Engineered to minimize dust buildup, maintaining tool longevity and ease of maintenance.

-

Enhanced Load Bearing – Sturdy build with reinforced segments to handle the pressures of industrial-level stone fabrication.

-

Easy Installation and Use – Simple to mount on CNC machines with quick-change functionality, ideal for busy fabrication environments.

CNC Stone Stubbing Wheel for Precision Grinding

$48.00

- – The Stone CNC Stubbing Wheel sets a new standard in stone surface processing with its expertly crafted diamond segments and robust iron core.

- – Tailored to handle the demands of granite, marble, and engineered stone grinding and milling.

- – Designed for CNC applications, providing precision grinding and smooth, high-quality polishing.

- – An invaluable tool in achieving flawless surface finishes.

Precision Grinding & Surface Milling

The CNC Stubbing Wheel is expertly crafted to provide seamless grinding, milling, and polishing on granite, marble, and other engineered stones. Its durable diamond profiling wheel ensures a high-quality finish and efficient material removal, making it ideal for calibrating countertop thicknesses and maintaining surface integrity. With a design focused on precision, this stubbing wheel offers an excellent solution for fabricators seeking premium results.

Constructed with high-grade segments and an iron core, the LINSING CNC stubbing wheel is built to withstand high-intensity use. Its enhanced durability and efficient processing speed enable stone fabricators to handle heavy-duty projects with ease, maintaining smooth, polished surfaces over long-term usage. This tool is particularly suited for high-demand grinding applications, providing consistency and reliability in every use.

Versatile Specifications for Adaptable Use

Available in a range of diameters (D50/86/100mm) and adaptable shank options, the LINSING stubbing wheel can be customized to meet the diverse needs of professional workshops. This flexibility, combined with the wheel’s ergonomic design, allows for precise thickness calibration on various stone projects. Equipped with a 1/2” gas flange, the stubbing wheel easily adapts to multiple CNC machines, making it an essential tool for any stone-cutting setup.

Key Features

Precision Surface Calibration

High Processing Efficiency

Adjustable Shank Options

Durable Construction

Reviews

There are no reviews yet.